BOM(Bill of Material)

ECOUNT's production management program can automatically calculate

the quantity of raw/sub materials required for production based on the BOM(Bill of Material).

Management of

production increase and

decrease using BOM

- Compose the number of raw/sub material required

to produce through the BOM. - The type and quantity of the raw/sub materials used

in the production is based on the BOM. - There is no need to manage the production

increase and decrease separately, as it is reflected

instantly when entering the goods receipt.

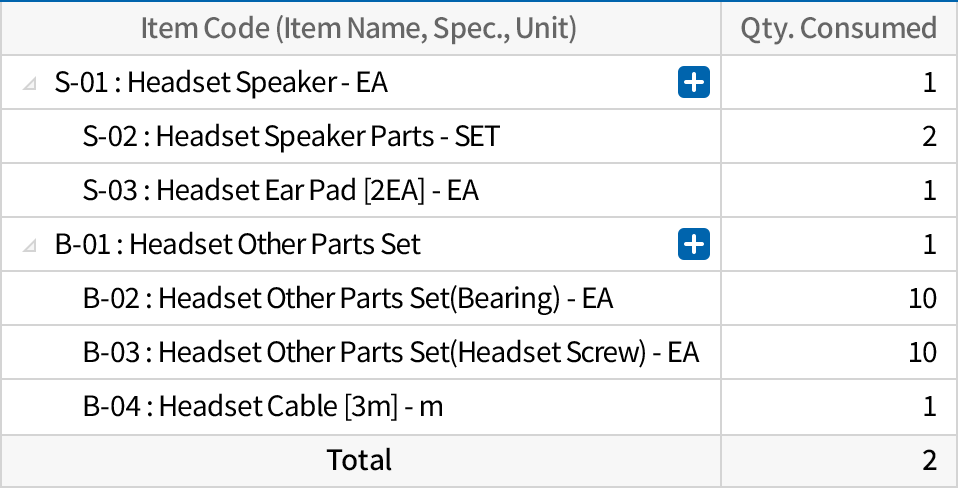

Apply the company's BOM system

- Register multiple processes according to the company's production flow.

- Compose the BOM with various units like EA, SET, KG, etc.

- Easily upload the BOM data in bulk using the Excel uploader.

Smooth ordering of

raw/sub materials without

disruption to the

production schedule

- Predict the quantity of raw/sub materials needed

for production in advance based on the BOM. - Calculate the quantity of raw/sub materials to be

used in advance and reflect in the ordering

process.

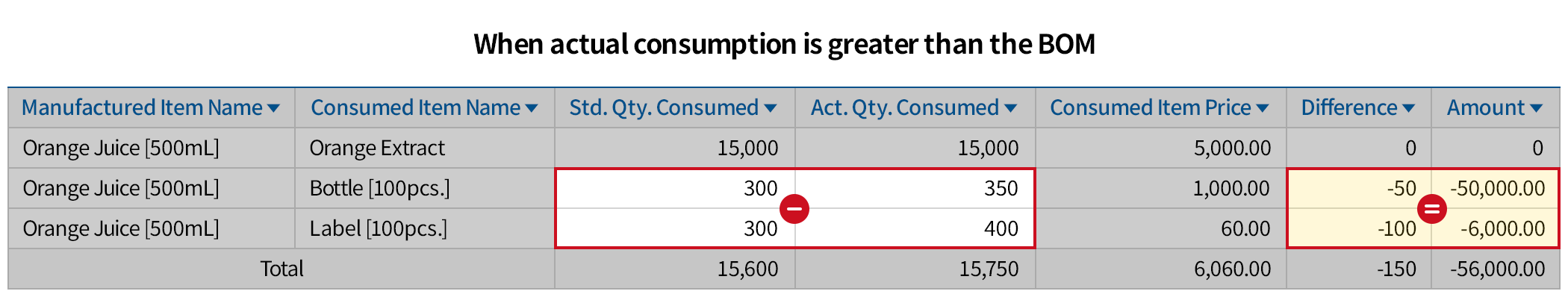

Comparison of BOM-based consumption and

actual consumption at a glance

- Apply the actual quantity of raw/sub materials consumed when inputting the production.

- Check the difference between the set BOM and the actual raw/sub materials used.

- Compare the cost based on actual consumption with the BOM-based cost.