Master Production Schedule (MPS)

Establish production plans and manage the ordering schedule

according to the production schedule through the Master Production Schedule.

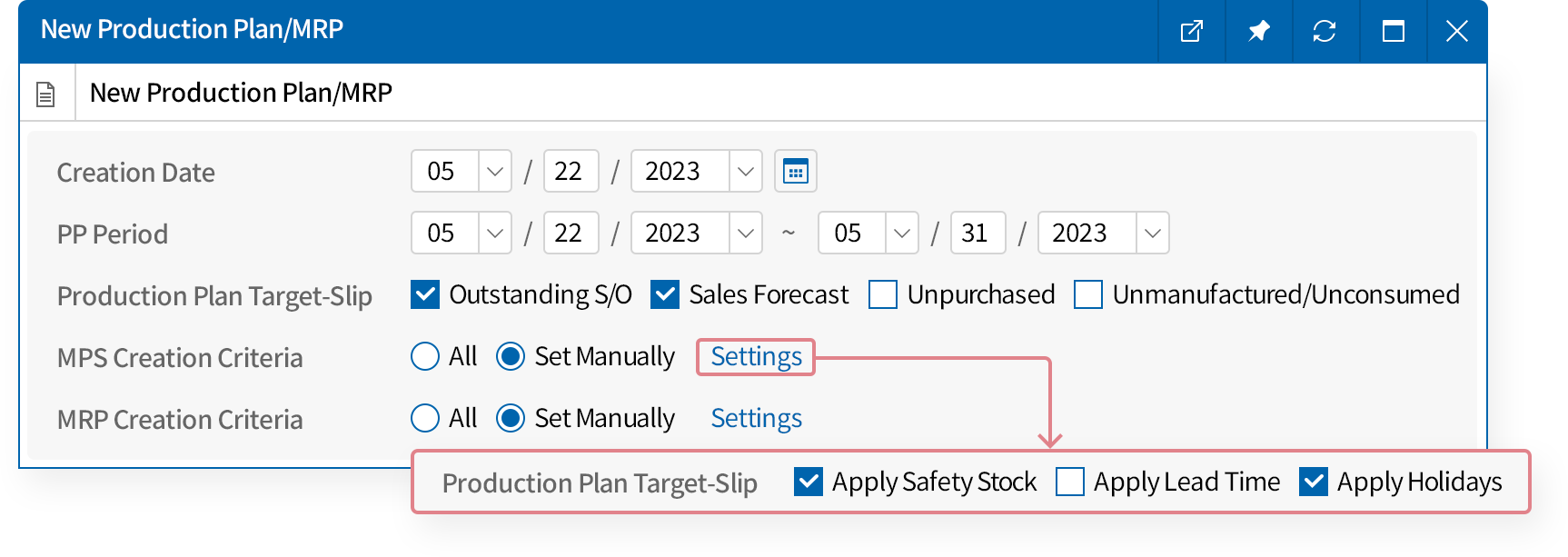

Establish Production Plans Based on Order (Sales) Details

- You can establish a Master Production Schedule (MPS) based on sales order (outstanding sales order),

sales forecasts, and more. - Production schedules can be planned by taking into account safety stock and holidays.

View Production Schedule at a Glance

- You can view the production schedule by date and by item.

- Plans can be directly modified as needed.

Order Raw/Sub Materials

Based on Production

Plans

- By linking the Master Production Schedule with the Material

Requirements Planning (MRP), you can check the required

quantities and procurement timing for raw/sub materials. - Utilize Material Requirements Planning (MRP) to establish

optimal order plans and generate purchase orders accordingly.