Quality Control (QC)

By utilizing ECOUNT ERP, you can analyze the processes and defect types where defects occur to reduce defect rates,

and enhance your competitiveness through continuous quality management and improvement.

Quality Management

Tailored to Your

Company’s Workflow

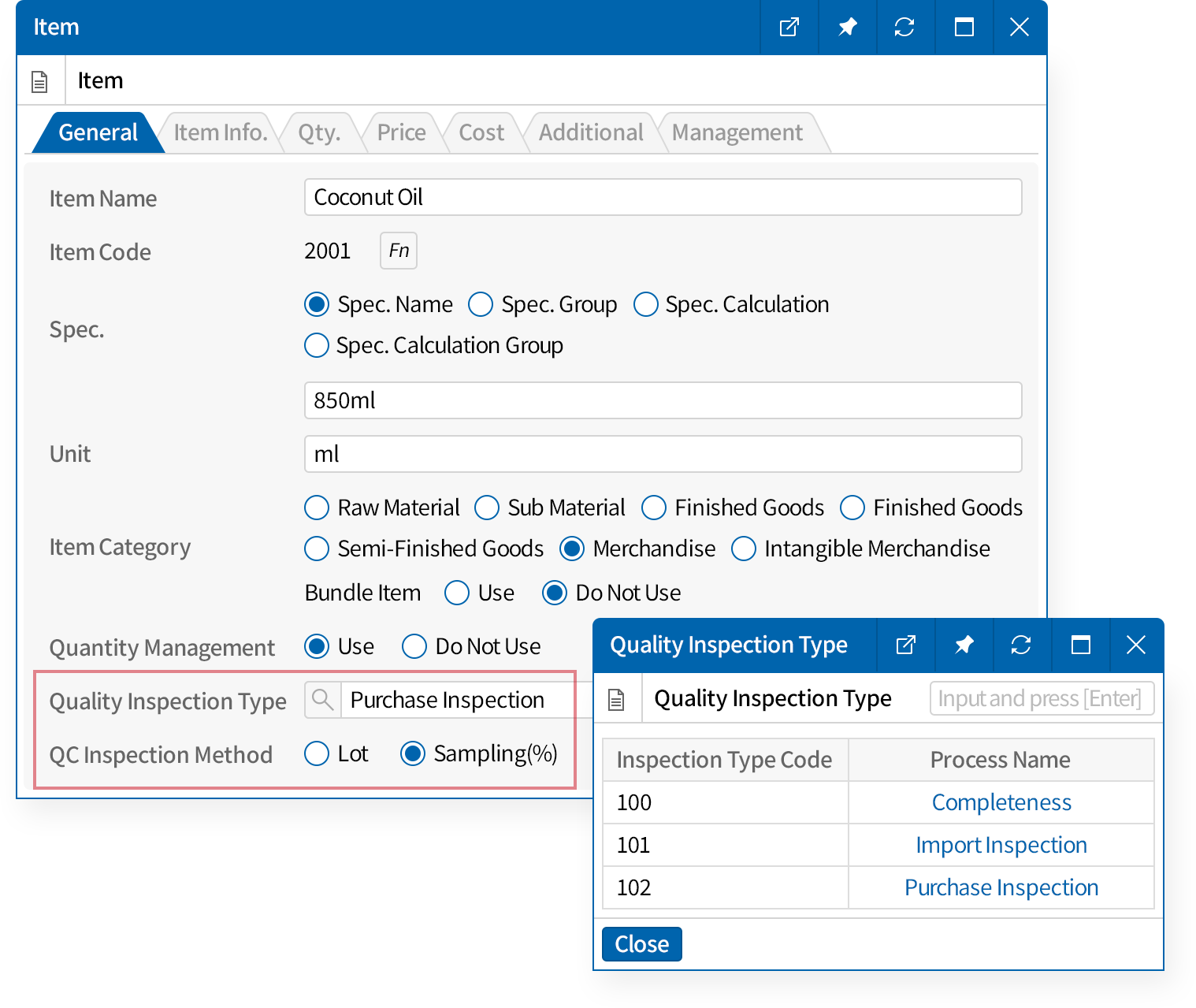

- You can register the inspection types currently

used in your company. - You can set detailed quality inspection methods

(sampling/lot) and inspection types

for each item. - Quality inspection requests can be automatically

generated when entering production/purchase slips.

Conduct Quality Inspections by Importing Purchase and

Production Records

- You can import created production/purchase order/purchase/sales order/sales slips to conduct quality inspections.

- You can determine and process the pass/fail status of quality inspections.

- Nonconforming quantities identified during the quality inspection process can be identified as defects.

Detailed Methods for Managing

Defective Products

- You can register and aggregate defect types by reason

to conduct defect analysis. - When entering defects, you can classify them as dispose/

disassemble/normal use according to the action. - You can deduct the inventory quantity of defective items

or enter them so that the inventory quantity remains unchanged.

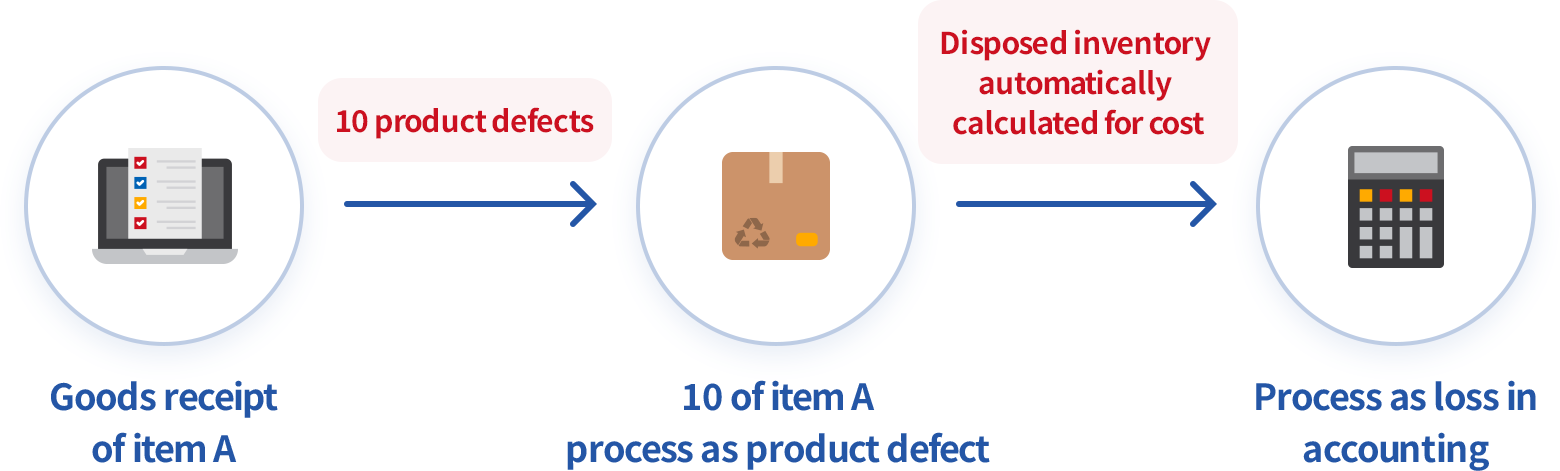

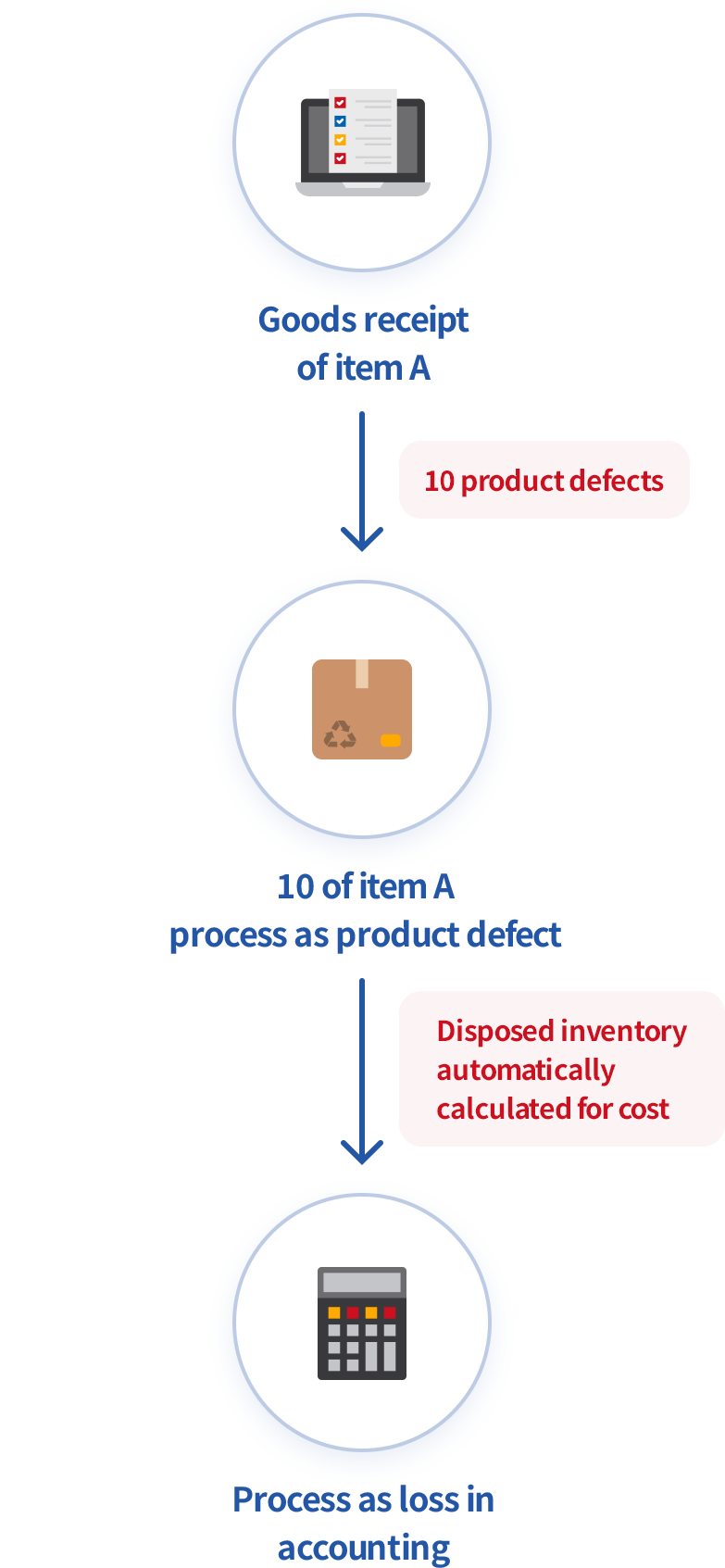

Seamless Defect Handling Linked with Other Operations

- You can import sales/purchase/goods receipt/location transfer slips to process defects.

- The value of inventory disposed of as defective is automatically retrieved during cost calculation and can be processed as a loss in accounting.

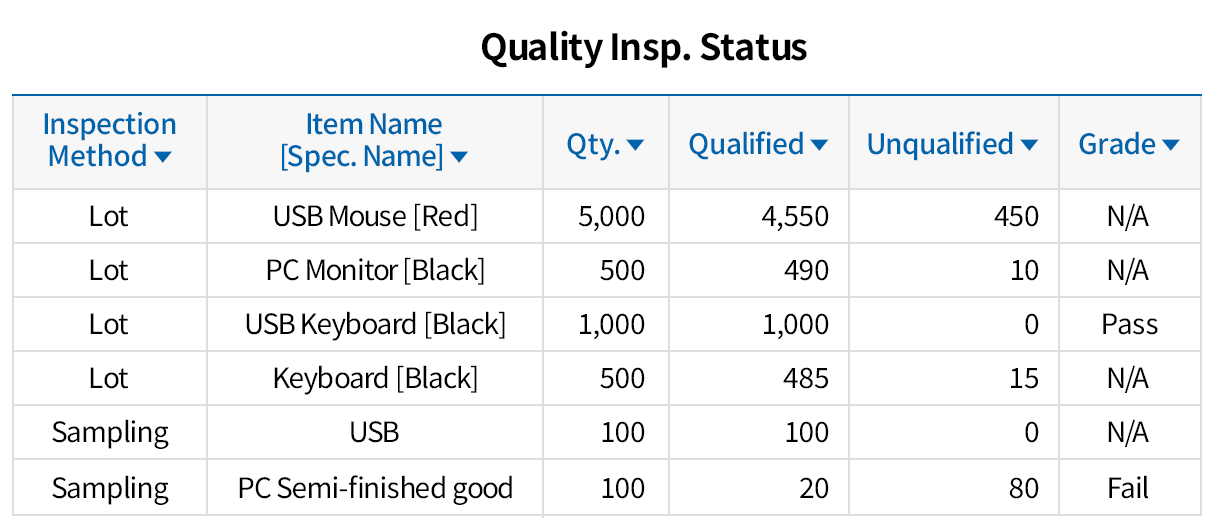

Diverse Reports for Quality Management

-

Identify the number of qualified, unqualified, and total

quantities by item according to inspection methods and types.

-

Check the defect rate statistics by comparing the defective quantity

to the production quantity for each process.