Features of Production Management

Experience ECOUNT's production management.

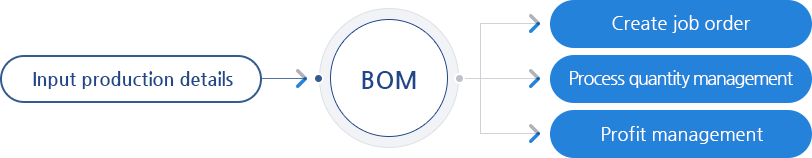

Configure the quantity of raw/sub materials and semi-finished goods in a BOM(Bill of Material),

and process all manufacturing management tasks based on the detailed BOMs.

No problem if different materials are used for a single manufactured good each time of production,

as you can register multiple BOMs for a single finished good, and cover all types of production.

Efficiently manage production by workshop management system.

In ECOUNT, all you need to do is enter the manufactured goods.

And then all the work including stock control for each process, job order, costing and profit management will be automatically processed by ECOUNT program.

Quantity Control by Process

In every production, stock quantites automatically adjust based on the BOM, where the consumed raw/sub materials decrease while finished goods increase.

Changes in stock quantities are immediately reflected in the inventory books, providing a history of where and when the materials have been moved or used.

Use the ERP search engine and view easily all the items' stock change history in report format.

Streamline production performance management with reports tracking manufactured and consumed items across various production runs and time periods.

Auto-create Job Order

The required raw/sub materials for a production are automatically included in Job Order being created.

The generated job orders can immediately be sent to each PIC by email.

You can also customize the job order format to fit your company's work.

Since you can import the entered job orders when creating production or purchase order data, a more accurate and precise work processing is possible.

You can also easily track the progress status by comparing job order history and the actual production status.

View the variance between the expected comsumed quantity based on the BOM and the actual consumed quantity in a production in report format.

Automated Cost/Profit Calculation

Cost is automatically calculated based on the unit price of raw/sub materials put in manufacturing.

Determine the profit amount and ratio by comparing the costing calculation with sales data,

and see the variance between the average estimated cost and the actual production cost by each item.

Easily analyze production reports to determine the unprofitable items and identify the finished goods needing cost reduction.

Outsourced Production Management

Register your outsourcing factories and easily manage their progress status and current stock.

Enable your outsourcing factories to enter the production details and issued goods by providing them with a user ID, and review their entries in the reports.

In addition, you can enter outsourcing expenses incurred during production by item, as well as process the expenses in accounting.

Handling Product Defects

The product defects from your production can be easily handled.

Simply enter the defective items, and stock quantities are automatically deducted depending on the defect process type.

Register the most frequent defects as distinct types to specify issues on items and generate a report essentials for determining the defect rate.

Quality Control

Register your company's own quality inspection fields.

Control inventory stocks according to the qualified items by recording which went through quality inspection that passed the quality inspection fields you set.

Automate the creation of a request for quality inspection at the time of purchase or production slip making to inspect all items without miss.

Workshop Management System

Use our program as workshop management system.

Register your processes, workflow, resources, and operations.

Set up the resources and hours required for each work.

Manage your assets, repair equipments and vehicles and efficiently operate them through our workshop management system.

Going further from a simple BOM management system, meet our more advanced workshop management system and control your operations and workshops.

In this way, with ECOUNT, you can manage your production based on the registered BOM,

making your production work flow and stock control more accurate and convenient than using Excel or another program.