WMS

(Warehouse Management System)

By utilizing ECOUNT’s WMS (Warehouse Management System),

you can assign individual numbers to each item and accurately manage inventory quantities, storage locations, and more.

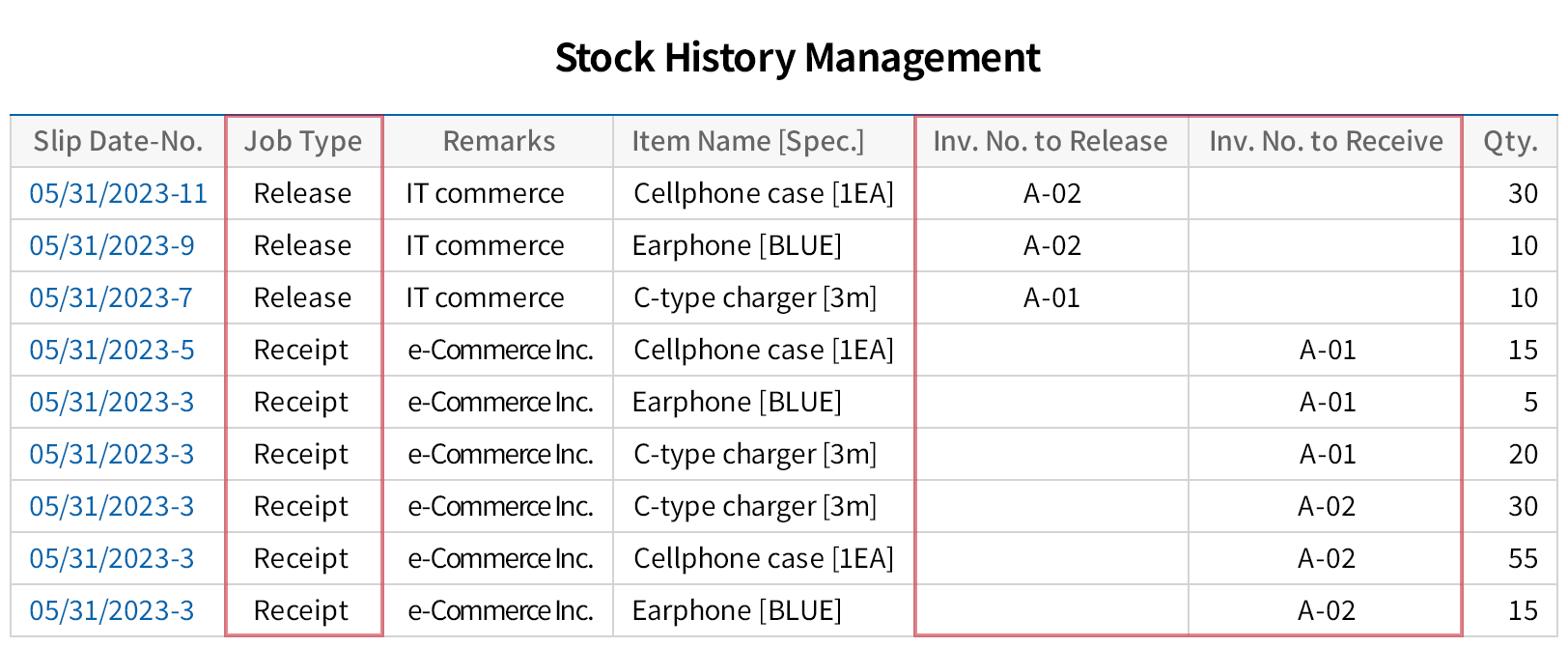

Detailed Inventory History Management with WMS

- You can assign a unique individual number each time inventory is moved.

- Through individual numbers, you can easily grasp and track the flow and detailed history of

each inventory item for receiving, shipping, transfer, and adjustment at a glance.

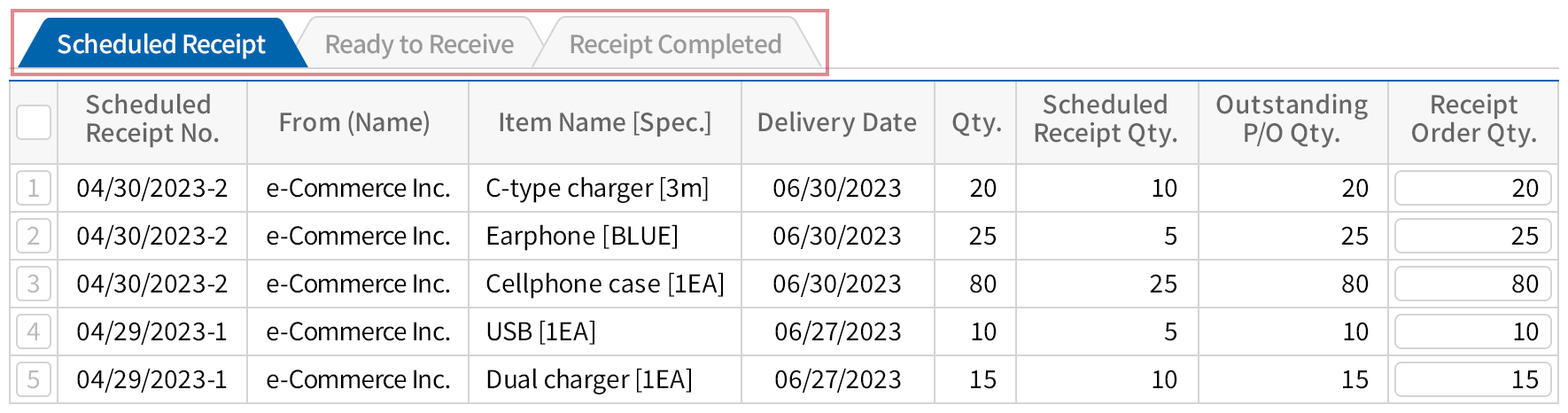

Real-Time Inventory Management and

Receiving/Releasing Schedule

- You can subdivide the process into stages such as scheduled, pending, and completed for

receiving/releasing operations, and manage according to the progress of each task. - Inventory quantities for each stage are reflected in real time,

allowing you to accurately identify the actual available stock in the warehouse.

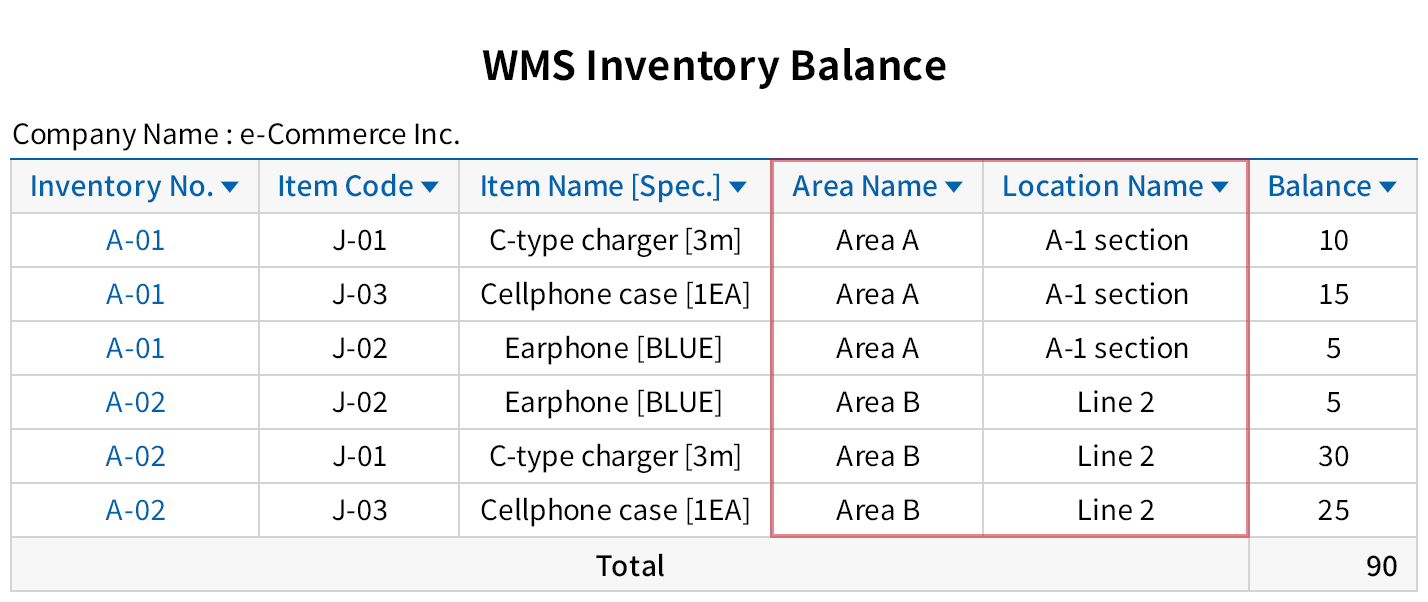

Inventory Management by Area/

Location within the Warehouse

- Easily check and move the current location of the inventory and

its quantity by segmenting the warehouse to area/location - In the WMS inventory status, you can instantly view

quantities by inventory number, item, and location at a glance.