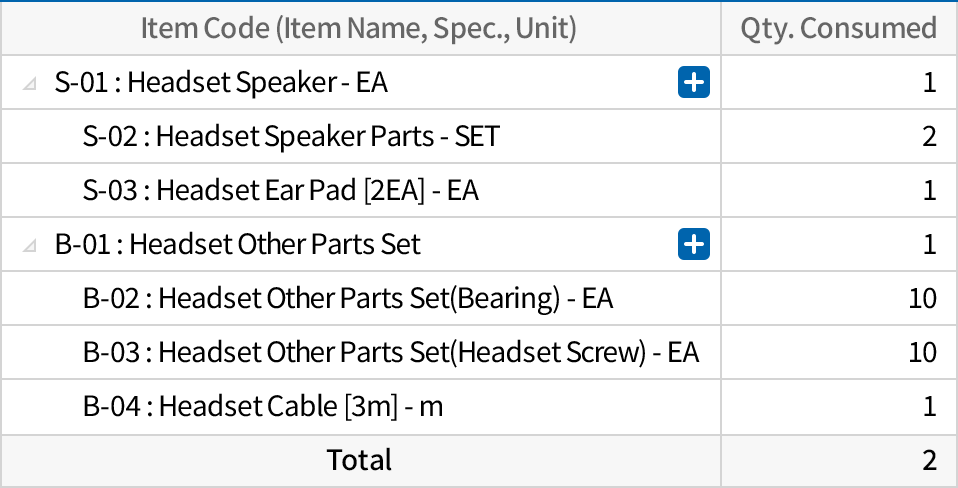

BOM (Bill of Materials)

ECOUNT's production management program can automatically calculate

the quantity of raw/sub materials required for production based on the BOM (Bill of Material).

Production Inventory

Management Utilizing BOM

- You can configure the quantity of raw and subsidiary

materials required for product manufacturing

using the BOM (Bill of Materials). - Based on the BOM, the system automatically calculates

the types and quantities of raw /sub materials to be used

in production. - As production receipts are entered, inventory is

updated in real time, eliminating the need for separate

production inventory management.

Apply Your Company's BOM Structure

- You can register multiple processes to match your company's production flow.

- BOMs can be configured using various units such as EA, SET, KG, and more.

- With the Excel upload feature, you can easily upload large volumes of BOM data.

Smooth Ordering of Raw/Sub Materials Without Distrupting

the Production Schedule

- You can forecast the quantity of raw and subsidiary materials required for production in advance based on the BOM.

- By pre-calculating the required raw/sub materials, you can place them in your purchase order ahead of time

Comparison of BOM-Based Consumption and

Actual Consumption at a Glance

- When entering production, you can apply the actual quantity of raw and subsidiary materials consumed on site.

- You can check the difference between the set BOM and the actual materials used.

- Compare costs based on actual consumption and BOM standards.