MRP (Material Requirements Planning)

By utilizing the MRP function, you can establish a material requirements plan to ensure that raw/sub materials are not in short supply.

This enables you to order the appropriate quantities necessary for production.

Material Requirements Planning (MRP) Linked with

Master Production Schedule (MPS)

- Based on the production schedule established through the Master Production Schedule (MPS),

you can procure the raw/sub materials required for production. - Even without manual calculations, the Material Requirements Planning (MRP)

is automatically established based on the production plan.

Establish a Systematic

Ordering Process through

Automatic Calculation

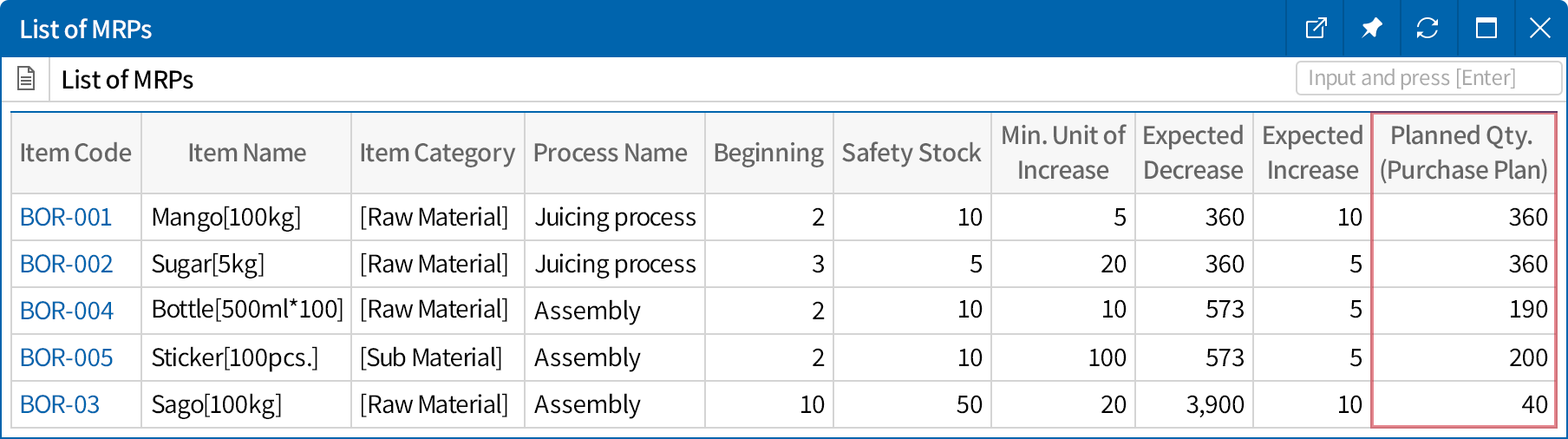

- Based on the BOM, you can flexibly apply safety stock,

lead time, holidays, etc., to determine the timing

and quantity for procuring raw/subs materials. - The required quantity, expected receipt quantity,

and necessary quantity of raw/sub materials for each

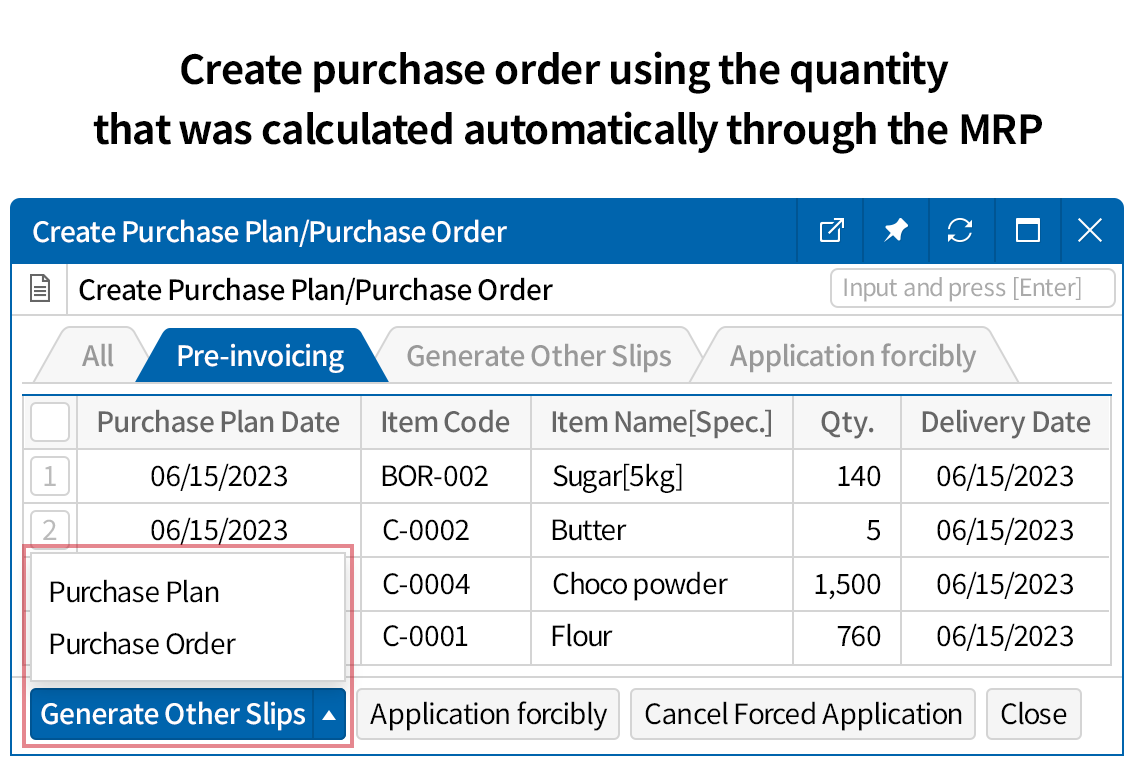

date to be used in production are automatically calculated. - Based on the derived material requirements plan,

the purchase plan is automatically established, and you

can instantly generate purchase orders by linking

with the purchase plan.